|

PackSys Global AG |

|||||||

Deutscher Text >>>

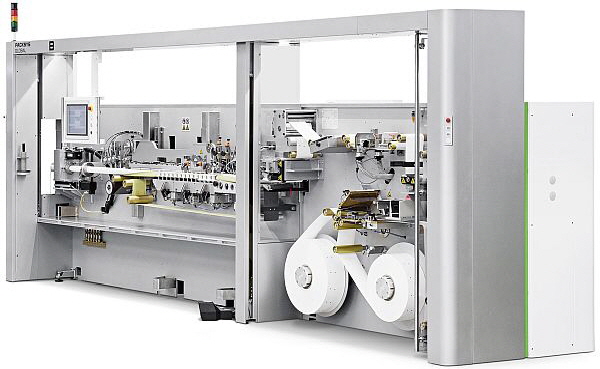

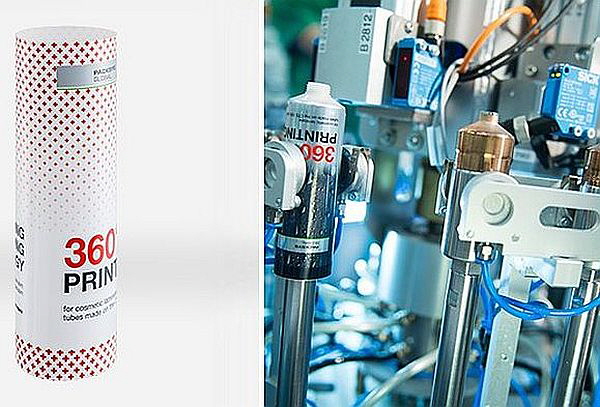

Solutions Oral care & cosmetic tube equipment - Info >>> PackSys Global offers complete lines and sets industry benchmarks Plastic and laminate equipment - Info >>> Combitool Solutions offers flexible solutions for plastic and laminate tube production with intelligent tooling technology. Plastic & metal caps equipment - Info >>> PackSys Global helps customers to design complete systems to produce caps from resins to the packed product. Aluminum aerosol can and collapsible aluminum tube equipment - Info >>> PackSys Global manufactures complete lines and is the world leader for decoration technologies and interior coating of cans. Hot stamping systems - Info >>> Madag Printing Systems provide a comprehensive range of flexible and reliable automatic hot stamping machines. Tube, can & cartridge packing - Info >>> Texa Packaging is the leading packing partner across the globe for packing unfilled laminate, plastic or aluminum tubes and aerosol cans and bottles.  LTR2 side-seamer produces unrivaled, invisible and strong seam quality Technology Inviseam® - revolutionized Side-Seam Technology PackSys Global introduced Inviseam® in its laminate tube machines a decade ago. Whereas most laminate tubes have an overlap, Inviseam technology allows butt-welding of the laminate, making the seam almost invisible to the consumer. Inviseam® is produced on the LTR2, which also allows for 360 degree printing, similar to extruded tubes but with the lower cost and higher quality possible from printing in the flat. This technology allows tube manufacturers to use laminate tubes for the cosmetic industry to give nearly the same feel and appearance as extruded tubes. Inviseam technology continues to be unrivaled in the market, ten years after its introduction. Your Benefits • Inviseam® technology makes the seam almost invisible to the consumer. • Allows laminate tubes to be used for the cosmetic industry. • Guaranteed seam strength quality.  360seam™ - new side-seam printing Technology 360seam™ is PackSys Global’s side-seam technology for cosmetic laminate tubes to meet the high quality demands from the market. This highly stable, perfectly accurate seaming process creates laminate tubes with 360° printed appearance showing no visible overlap to the consumer. Yet tube manufacturers continue to have all the decoration possibilities of flat printing. 360seam™ technology takes advantage of ‘combination presses’ where flexo, silk-screen and foil stamping can decorate laminate in one step. Not only is 360seam™ technology an advanced decoration solution for tube manufacturers, it is more sustainable and kinder to the environment; since its direct printing eliminates the need for labels. Also, laminate technology allows use of multiple thin layers to give the same look and feel in a thinner tube compared to an extruded tube. PackSys Global has developed a new generation of side- seamers for its laminate tube lines specifically designed to cost effectively produce small batches of high quality cosmetic laminate tubes with 360seam™ printing: CTS 80 (80 tubes/minute) and CTS 125 (125 tubes/minute). Your benefits • 360seam™ allows 360 printing with small overlap • Highly stable, perfectly accurate seaming process • 360seam™ has all decoration possibilities of flat printing • Ideal for small batch production or startup businesses  Visit us at the K exhibition. We are looking forward to welcoming you on our stand (hall 3, stand D90). |

|||||||

|

|

|||||||

|

|||||||

|

K Messe Spezial |

|

Das Messe-Spezial rund um die K Messe - präsentiert |

|

≡Messe-Spezials |

|||||||

|

|

|||||||

|

≡Messeinformationen |

|||||||

|

|

|||||||

|

≡Varia |

|||||||

|

PackSys Global AG

PackSys Global AG