Thermoplay S.p.A.

|

||||||||

|

Product range >>> Markets >>>

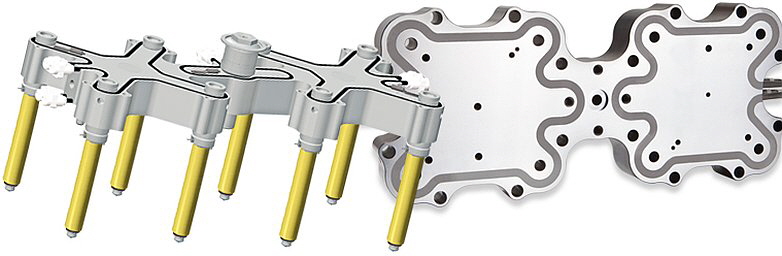

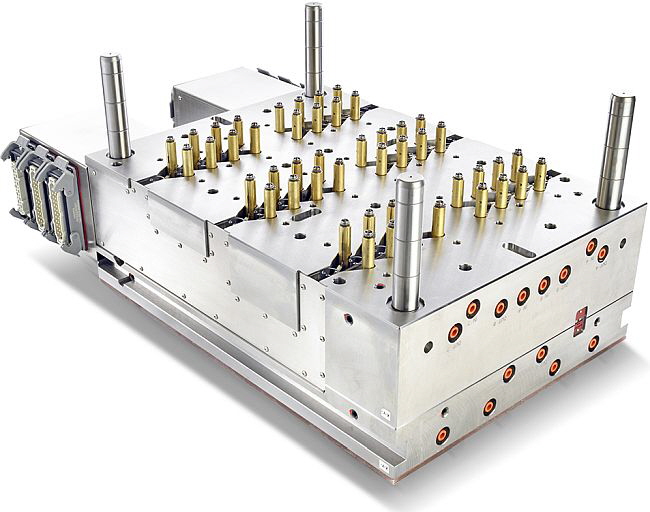

Product range Our product range, designed and built exclusively in-house, includes a comprehensive selection of standard and special hot runner systems. We can satisfy all types of configuration needs for any market application. We offer complete hot halves as well as temperature control units, flow analysis, customized designs, simultaneous injection of different colors and materials. Temperature controllers, designed and manufactured according to the highest safety and quality standards, guarantee a perfect control of the hot runner systems and, consequently, of the molding process. Produkt-overview • Nozzles and single nozzles >>> • Manifolds >>> • Special solutions >>> • Temperature contollers >>> Nozzles & single nozzles The modular components simplify maintenance as parts can be replaced directly in the machine. Special patented heater: • Constant thermal profile • Significant energy savings Tips in special sintered steel: • Optimal thermal conduction • Wear resistant Features: • Different lengths • Single nozzles available for all tip types • Colour change option The following nozzles series are available: • TF: suitable for all thermoplastics • TD: simple design and manufacturing of nozzle seat • KS: Standard multi tip and side gate solutions • DL & DN: Special range of unique multi tip and side gate solutions Produkt-overview • Special solutions DL/DN-series >>> • TF - TD series nozzles >>> • KS series nozzles >>> • Single nozzles >>> â–ºCatalog >>>  New Thermoplay nozzles “TF” and “TD” series for multicavity moulds Manifolds Features • Balanced manifold layouts with special inserts (conical plugs) allow multilayer channels and direction changes. • Vast range of customised and standard configurations with optimised melt channels for each application. • Even temperature profile for all applications. • High quality steel. • Flow analysis used to design special application and family moulds. â–ºCatalog >>>  Flow analisys Injection systems from Thermoplay are defined following careful analysis of the injection material, the size and weight of the item to be moulded, and the expected moulding cycle. Using flow-analysis software and 3D simulation techniques, the company balances the hot runner carefully to ensure perfect cavity filling for precise production of part details. Conical plugs inserted in all the manifolds eliminate the possibility of stagnation zones. Balancing The flow paths having the same length and channel sections create a natural balance, while the distributed filling pressure in all the mould chambers ensures moulding of identical parts. The special structure of the manifold allows the nozzles to be assembled at low temperatures, to avoid out-of-axis movements while the operating temperature is reached. Special solutions Thanks to many years of improved experience in hot runner systems design and manufacturing, Thermoplay is able to provide a complete range of standard and special injection systems, suitable for any kind of application including multiple material components and application to large moulds: • DL1B-DL8B - special edge gate nozzles. • DL90 - multi-tip edge gate nozzle. • DN5 - multi-tip nozzle. • Complete assembled hot half system. • Special hot half system for injection blow moulding. Success in the hot running moulding depends on the perfect cooperation with customer in the design process, with simple rules application in process control Produkt-overview • Edge gate nozzles DL1B-DL8B >>> • Multi-tip edge gate nozzles DL90 >>> • Multi-tip special nozzles DN5 >>> • Hot halves >>> • Injection blow moulding system >>>  48 drops open gate Thermoplay hot half Videos

Temperature contollers TH-M6 3-6-12 zones General features • Synchronous increase of temperatures • “Slave” function: each zone can be linked to another with similar thermal behaviour • Plastic leakage alarm • Collective modification of all zones • Immediate and complete diagnostic • Efficient soft start (phase modulation adjustment) • Elimination of absorption peaks on three-phase • 2 independent set points • Multi language • Max working temperature: 50°C • Main protection with circuit breaker • 3-phase 400V supply or 3-phase 240V • CE Certification â–ºTechnical info >>>  Gammaflux G24 Gammaflux temperature control systems deliver superior control, reliability, ease of use, and value to every application on which they are used. All Gammaflux controllers feature Triangulated Control Technology® along with exclusive Power Priority® and Mold Doctor®, for the ultimate in temperature control. The G24 product line provide control for applications from 18 to 480 zones of temperature control featuring the following benefits: • Easy to use • Cost effective • Compact size • Fast start up and operation • Flexible configuration • Improved Interlocks • Mold Doctor® • Early Material/Leak Detection Benefits that can be realized from improving temperature control on your application include: • Enhanced part quality • Reduced scrap • Improved part weight consistency • Material savings • Increase profit margins. All Gammaflux temperature controllers come with a full 5-year warranty (2 year warranty on touch screen interface) and are backed by the industry-leading worldwide service and support. â–ºFor more information visit www.gammaflux.com  Webcreator online WEBCREATOR is a web-based design application for configuring Thermoplay Hot Runner Systems with standard nozzles and accessories. This generates high quality CAD 2D and 3D models reducing the production time. The hot runner system is freely configured in relation to the distance between the nozzles and accounts for the polymer processing conditions. The diameter of the manifold channels, as well as of the descent holes to the nozzles and the injection bushing size are configured to suit. After configuration the 2D drawings and 3D models are generated in the selected format and sent by email to the user in a single zipped file, which also includes the configuration sheet and part list (in pdf format). Any configurations made can be modified to generate a new drawing later. WEBCREATOR does not perform any check on the configured system in relation to the injected polymer. â–ºWebcreator >>> MARKETS • Automotive >>> • Electrics & electronics >>> • Housewares & white goods >>> • Logistics >>> • Medical >>> • Packaging & closures >>> • Personal care >>>

|

||||||||

|

|

||||||||

|

Products |

||||||||

|

||||||||

Kunststoff-Deutschland - das Internetportal

für die deutsche Kunststoff-Industrie

☰Menü

|

Partnerwebsites: Kunststoff-Schweiz Kunststoff-Guide |

Thermoplay S.p.A.

Thermoplay S.p.A.