|

Promix Solutions AG |

||||||||||||||

|

Deutscher Text >>>

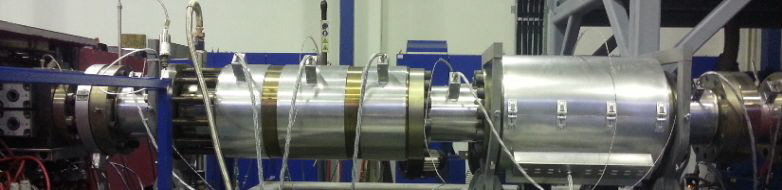

Foam extrusion - Info >>> Promix foam extrusion - advanced solutions for physical foaming in extrusion processes With physical foaming significant material savings are possible for many extrusion processes. Foam extrusion systems from Promix are setting new standards in the production of microcellular foam products with very homogeneous cell structure and with previously unreached process stability. Unique key components and broad process knowledge are the basis for our innovative technologies. Our systems work with eco-friendly CO2 and N2 blowing agents and are very easy to integrate into existing or new extrusion lines. Depending on the application, density reductions of 5 % to more than 70 % can be achieved. More than 100 systems sold worldwide • Significant cost savings due to density reduction by 5 % to 70 % • Highest foam quality and outstanding process stability • Easy installation into existing or new extrusion lines • No license fees by Promix  Microcellular foams produced with Promix foam extrusion system Key to success • Promix gas dosing stations especially developed for physical foaming, for highest dosing accuracy and very safe and easy operation • Patented high efficiency static and dynamic mixing systems with very short installation length • Unique patented P1 cooling mixer technology for outstanding foaming results • Die modifications for foaming, annular dies for light foam applications • Inline viscosity measurement for real time monitoring of raw material and process conditions • Broad consulting and project support • Pilot testing and sample production in our test facilities Application examples Promix foam extrusion systems are presently in operation for a wide variety of applications, and for many different polymers. Our foaming systems can be installed on lab and pilot lines with a little as 5 kg/h, and on up to industrial lines with more than 2000 kg/h throughput. Our systems produce very homogeneous microcellular structures which create exceptionally high quality foam products with very low densities and outstanding mechanical properties. Following are some examples:  XPS, XPE, XPP foams - Info >>> Key components for the production of XPS, XPE, XPP, XPET low density foams Promix offers relevant key components to optimize production of low density foams such as fabrication of XPS insulation boards, XPE foam film or XPP, and EPE thermoforming sheet. Implementing Promix key equipment generally results in lower foam densities, improved cell structure and an increased line output, leading altogether to significantly lower production cost. Whether it is a tandem or long twin screw line, thermal insulation boards, packaging film or insulation for tubes or pipes: we will analyze your current line concept and propose a solution to increase your profitability. P1 Cooling Mixer - Info >>> Promix P1 Cooling mixer technology is a unique combination of a highly efficient static mixer and a powerful cooler. The novel patent-registered technology pushes the boundary when it comes to cooling of polymer melt and other viscous fluids. The simultaneously occurring mixing and cooling effects in the P1 cooling mixer allow a very efficient cooling very close to the solidification point of the melt without the risk of freezing or building of deposits. The melt temperature is homogenized over the whole cross section. Depending on process requirements, the ideal melt temperature can be exactly adjusted and kept constant over time. Melt blenders for extrusion - Info >>> Do you wish to optimize your extrusion process? Promix offers you effective static mixer and melt blender solutions including extrusion housings at low investment cost. Q1 Annular die for the production of EPS (XPS), XPE, XPP foam films - Info >>> The annular die technology has a major influence on the quality of EPS (XPS), XPE and XPP foam films. Promix Q1 annular die technology unifies 20 years of experience in designing and manufacturing of annular foam dies. The particular construction of Promix Q1 annular dies (patent pending) allows further reduction of foam density and film thickness tolerances. This leads to significant savings in terms of raw material and production costs. CO2 and N2 Gas dosing stations for physical foaming - Info >>> Die Promix Gasdosierstationen für physikalisches Schäumen wurden speziell auf die Bedürfnisse in der Schaumextrusion abgestimmt und entwickelt. Promix Gasdosieranlagen zeichnen sich durch eine hohe Dosiergenauigkeit, Zuverlässigkeit und einfache Bedienung aus.

Benefits of Promix key components for low density foams XPS Insulating board  • Uniform cell size and more consistent foam structure • Uniform cell size and more consistent foam structure• Increased throughput, especially for thick boards • Lower foam density • Faster start-up time • Savings of blowing agent XPE foam film and profile  • Lower foam density • Lower foam density• Uniform cell structure • More narrow thickness tolerances PS foam for food packaging (XPE)  • Lower foam density • Lower foam density• Increased stiffness/rigidity • Improved thermoformability • More narrow thickness tolerances Inline viscosity measurement - Infos >>> Viscosity measurement, accurate and inline - True real time quality control Control the production quality of your extrusion line with Promix Visco-P continuously and in real time. Avoid poor production quality issues and scrap. Visco-P is a true inline viscometer which measures viscosity directly in the melt stream and requires no bypass. The Visco-P continuously monitors raw material quality and process conditions. Convince yourself. Ask us for a test unit.  Promix® Visco-P for accurate inline viscosity measurement in extrusion Your benefits • Continuous real time control of raw material quality and process conditions • Very accurate inline viscosity measurement without bypass • Suitable for all viscous fluids • MFI / IV-calculation mode • Will be used in combination with Promix static mixers leading to additional value by improved melt and temperature homogeneity How it works A special Promix static mixer module, installed in the extrusion line, is the physical point for measuring process variables. The calculated results are displayed continuously and in real time on an industrial PC with touch screen. In addition to measuring the melt viscosity, the Visco-P will also calculate the MFI or IV value of the real melt. The Promix static mixer module creates excellent blending of the polymer melt which improves thermal homogeneity and surface quality, reduces thickness tolerance variations of the extrudates, and often leads to an increased output rate. Visco-P is in operation in many applications such as PET and PE extrusion and for the processing of polymer melts containing blowing fluids. Static mixers - Info >>> Industry leader for static mixer solutions in plastics processing • Solve your quality issues in injection molding or extrusion • Increase your productivity • Save production cost  Verschluss ohne (links) und mit Promix® Mischdüse (rechts) Promix® static mixer working principle

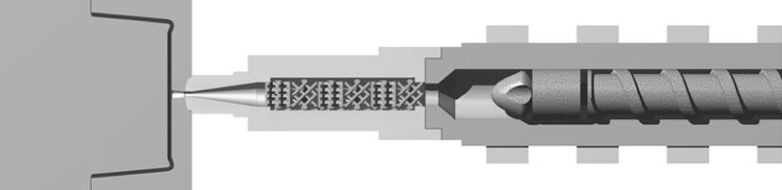

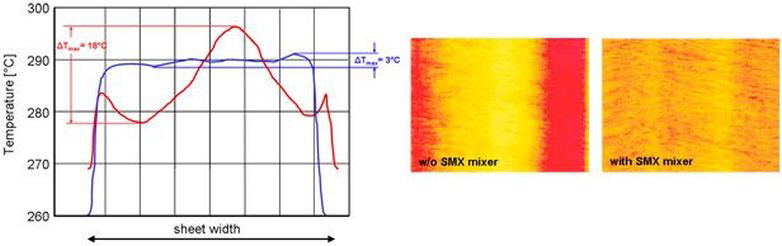

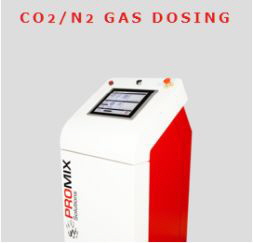

Promix static mixers offer you • High mixing efficiency with minimum pressure drop • Shortest installation length • Low shear stress • Maintenance free operation Mixing nozzles and static mixers for injection molding - Infos >>> You can solve many of your today problems in a fast and cost effective way without interrupting your production. Find the hidden potentials to further process optimizations. Save master batch costs of up to 30 % or reduce the cycle time. For more information please click on the links below: • No color streaks and flow lines • Improved surface appearance • Better incorporation of regrind material • Better balancing of cavities in hot runner systems • Better tolerances • Increased tensile strength • Close to maintenance-free processing of liquid silicone rubber â–ºCase studies â–ºMixing Nozzle Finder Promix mixing nozzle concept The Static Mixer is installed directly in the nozzle of the injection molding machine. You can rely on an experienced partner replacing your existing nozzle with the suitable complete Mixing nozzle from our extensive mixing nozzle portfolio. Most of the mixing nozzles can be delivered within 1 to 2 weeks. â–ºMixing nozzle inquiry form  Promix® mixing nozzle for injection molding Melt blenders for extrusion >>> Do you wish to optimize your extrusion process? Promix offers you effective static mixer and melt blender solutions including extrusion housings at low investment cost. Promix melt blenders offer you • Higher throughput • Excellent distribution of all additives • Consistent quality and optimal inflow of melt into the die • Elimination of flow lines • Homogenious temperature and velocity Application examples: For more information please click on the links below: • Cable sheathing • Compounding • Extrusion blow molding • Pipe extrusion • Rigid PVC & rubber extrusion • Sheet & profile extrusion • Thin film & blown film extrusion • XPS foam boards Promix melt blenders for effective temperature homogenization  Thermoscan of PE coating film with and without Promix® melt blender What we offer • Design, layout and manufacturing of melt blenders / static mixers • Custom-made housings including heater bands and thermocouples • Short delivery times • High quality standard â–ºMelt blender inquiry forms extrusion Gas dosing stations - Info >>> CO2 and N2 Gas dosing stations for physical foaming Promix Gas Dosing Stations for physical foaming have been developed to suit the specific needs of foam extrusion applications. Extremely high dosing accuracy, reliability and easy operation are the key features of Promix gas dosing systems. No matter if process monitoring with trend charts and user settable alarms, data acquisition, flow match with extruder output and many more, Promix gas dosing units provide all the required features for state of the art foam production. Furthermore, implementation in extruder control via fieldbus system is also possible.  Promix gas dosing system for physical foaming Main characteristics Promix gas dosing stations • Massflow from 1 g/h up to 10'000 g/h • Dosing pressure up to 680 bar • Convenient operation via 12,1” Touch Screen • User settable limits for full process control • Trend charts for pressure and flow over time • “Flow match” function to synchronize mass flow with extruder output • Implementation in extruder control via fieldbus system possible • Data acquisition via USB port • Remote maintenance capability

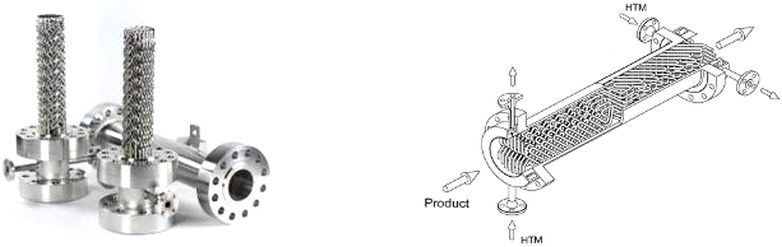

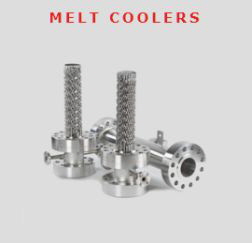

Melt Cooler - Infos >>> Melt Coolers and Heat Exchangers Do you wish to cool down your polymer melt? Promix offers you very efficient melt coolers and heat exchangers for viscous and high viscous fluids and melts. Promix Melt Coolers improve your process • Very high cooling efficiency and accurate outlet melt temperature control • No fouling or blocking problems due to a well-mixed single flow • Narrow residence time distribution • Short installation length • Low pressure drop Melt Cooler for highest efficiency  Melt Cooler concept In cooling processes viscous fluids tend to deposit at the cooling wall sections (fouling) leading to reduced cooling efficiency. In the Promix Melt Cooler (PMC) the melt flows in a single stream through the cooler. The cooling media flows in special pipe bundles arranged similar to those of the Promix mixing elements. The intense mixing together with the very high heat exchange surface area leads to effective cooling with very limited risk of fouling. Due to a void volume of about 75 % the resulting pressure drop in a PMC is rather low. The PMC can as well be used for gentle heating with only small temperature difference between heating media and fluid. Fill in the PMC inquiry in order to get an offer or contact our experts for further questions.  Promix Melt Cooler in operation New product New gas dosing model Promix supplies CO2 and N2 gas dosing systems, which were especially developed to suit specific needs in foam extrusion. The devices are characterized by an extremely high dosing accuracy, reliability and easy operation. With the NC350, Promix is expanding its portfolio with a model that can dose both, nitrogen and CO2. Further characteristic of the NC350 is its large dosing range from 10 - 10'000 g/h. This makes the unit suitable for use in R&D as well as in traditional production environment. All gas dosing systems were redesigned in autumn 2019. Accessibility was improved and the units were given a new and more streamlined appearance.  Sustainability Eco-rPET reduces plastics consumption in packaging Packaging solutions made from Eco-rPET are 10% to 20% lighter than conventional PET packaging. Depending on the application, they can be manufactured translucent or in any desirable color. The pearlescent effect gives the packaging a very elegant and high-quality look and feel. Thermoformed trays and cups made from Eco-rPET feature excellent rigidity and are insensitive to scratch marks making them suitable to safely stow berries or other delicate foods. This helps not only to reduce food waste but also protects the environment, as each produced tray uses 20 % less plastic. It goes without saying that lower plastics consumption is significantly cutting manufacturing cost. Eco-rPET packaging can be produced from recycled bottle flakes and is fully recyclable after being used itself. It can be manufactured on any existing or new PET sheet extrusion line by incorporating Promix technology. By adding smallest amounts of environmental friendly gases, microcells are generated, resulting in a lighter product weight. Promix supports film and packaging producers worldwide throughout the whole process: from planning to implementation to commissioning. Visit us at the Fakuma. We would be pleased to meet you on our booth: Halle A2 – Booth 2105 |

||||||||||||||

|

|

||||||||||||||

|

Product categories |

||||||||||||||

|

||||||||||||||

|

|

|

|

≡Messe-Spezials |

|

|

|

|

|

≡Messeinformationen |

|

|

|

|

|

≡Varia |

|

|

|

|

|

|

|

|

|

Fakuma Spezial |

Promix Solutions AG

Promix Solutions AG